Research

The Structural Metallic Materials Group at Northwestern University, supervised by Prof. David C. Dunand, focuses on the mechanical behavior of metallic alloys, composites and foams/microlattices. Concurrent research also addresses advanced processing techniques (e.g., to fabricate novel composites and foams) and microstructure characterization (e.g., to link the observed microstructure to the measured mechanical properties).

Pyrometallurgical recycling of "black mass" from spent lithium-ion batteries

Ming Chen, Maryam Al-buainain, Na Gong,

We study the recycling of "black mass" from spent lithium-ion batteries via pyrometallurgy in a sustainable manner, focusing on thermochemistry and resulting microstructure of stable end products; in-situ x-ray diffraction provides a window on the kinetics of reactions, as well as the formation and disappearance of intermediate products.

Hydrogen reduction of mixed oxides for CO2-free synthesis of ferro-alloys

Maryam Al-buainain,Ya-Chu Hsu

We are proceeding with a fundamental material-science investigation of mechanisms of H2-reduction of blends of iron oxide and other element oxides, and their effects on the resultant steel or ferroalloy microstructure and mechanical properties.

Additive Manufacturing of Alloys

*recently completed project/researcher graduated

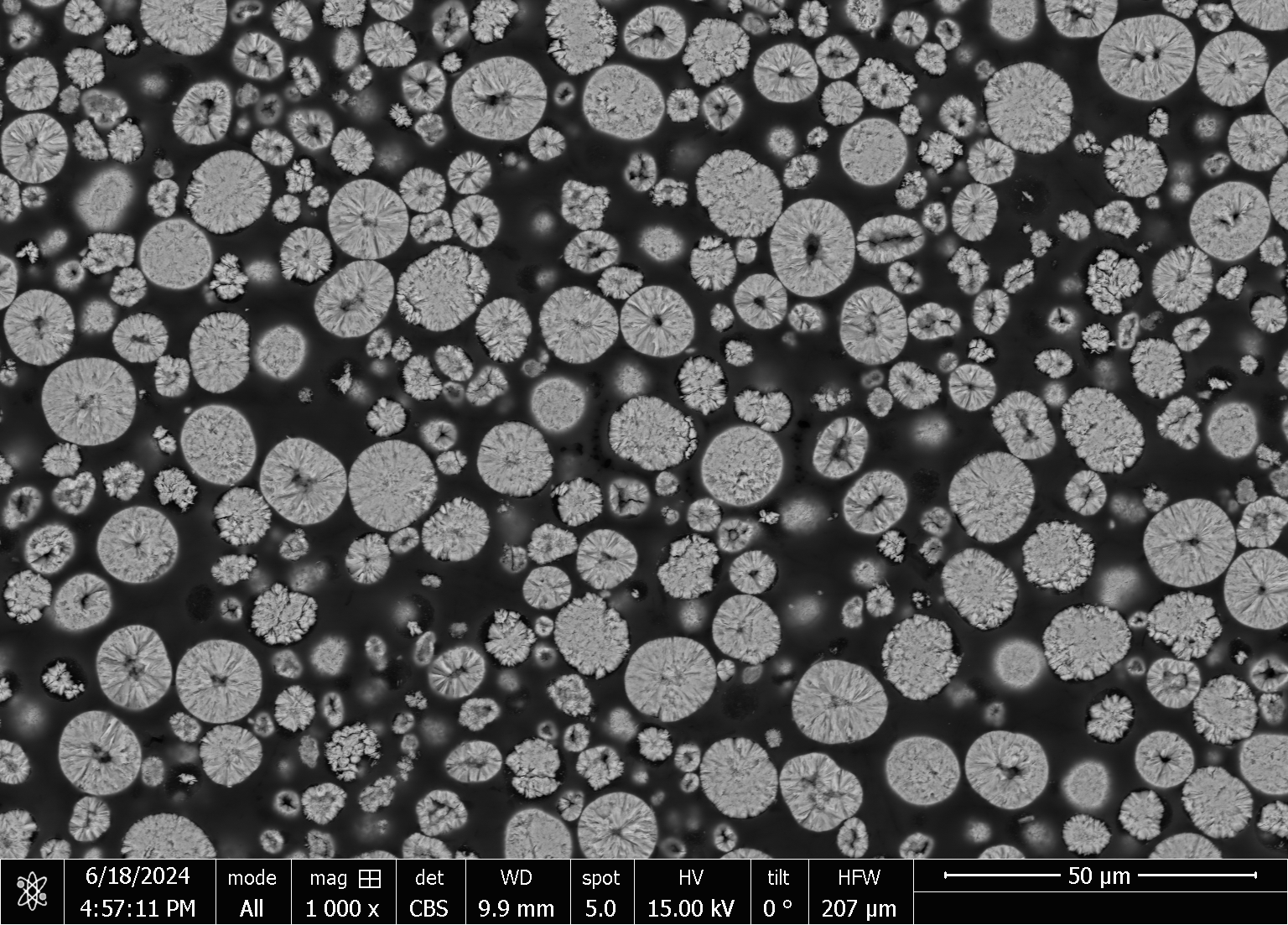

Selective laser melting

Near eutectic Al-Ce-Ni based alloys

Tiffany Wu, co-advised by Dr. Alex Plotkowski, Dr.Amit Shyam, and Dr. Ryan Dehoff, Oak Ridge National Laboratory

Near eutectic Al-Ce-Ni based alloys cast in bulk form show good strength and ductility. Our research focus on these alloys manufactured via selective laser melting and containing ternary and quaternary alloying additions. Preliminary research done at ORNL has showed promising strengths in eutectic Al-Ce-TM system, whose microstructures and mechanical properties (including creep) are being investigated

Hierarchically strengthened aluminum-based superalloys

Clement Ekaputra,Ismael E. Coello,Logan White and Dr. Jovid Rakhmonov; co-advised by Dr. Jon-Erik Mogonye, Army Research Laboratory

We aim to design cast and additively-manufactured aluminum alloys with superior creep performance for high-temperature applications. We develop an understanding of the microstructure and mechanical properties of alloys combining multiple strengthening mechanisms, such as precipitation and solid-solution strengthening, as well as the effect of processing technique.

Additive Manufacturing of Meteoritic steel

Samantha Maness;

We use iron-nickel alloys with meteoric composition, atomized and processed via additive manufacturing techniques (direct-ink writing or selective laser melting), to create structural materials with high strength and toughness for the construction of pressurized Martian habitats.

3D ink printing/sintering

Metals and alloys

John Misiaszek , *Chun-Te Wu, and *Dr. Christoph Kenel

3D ink extrusion printing is studied as an emerging processing technique to fabricate metals and complex alloys from pre-alloyed, elemental or compound powders. Combining different oxides or hydrides allows to create alloys directly from blended feedstock, further reducing the costs and risks related to fine metal powders typically used in beam-based AM.

Ceramics and composites

Dingchang Zhang, *Simon Moser, *Dr. Christoph Kenel, *Pengyu Chen, *Prof. Binna Song, *Jens Sesseg, and *Micha Calvo

3D-extrusion ink-printing combines the formulation and 3D deposition of an extrudable ink containing metal, ceramic or composite powders with an isothermal sintering step. This allows to process brittle alloys, ceramics and composites that cannot be processed by beam-based AM

3D Ink-Extrusion Printing of Thermoelectric Materials

Alexander Proschel, Dr. Ming Chen,and Yunjia Zhang; co-advised by Dr. Donna Guillen (INL), Professor Jeff Snyder (NU), as well as colleagues at Aerojet Rocketdyne, Inc., Jet Propulsion Laboratory, and Idaho National Laboratory (INL)

Thermoelectric (TE) materials can convert into electricity some of the lost energy due to waste-heat dissipation (power plants, engines, materials processing, etc.), and, inversely when subjected to an electrical current, they operate as heat pumps, thus providing solid-state refrigeration.

Freeze-Casting of Metals and Ceramics

*recently completed project/researcher graduated

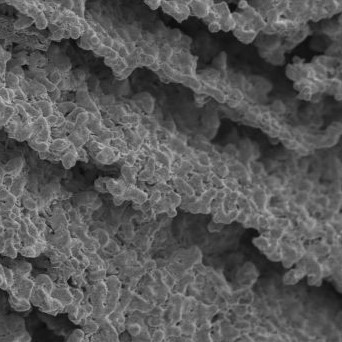

Freeze-Casting of Iron Foams for Iron-Air Batteries

Samuel Pennell,Jacob Mack,*Stephen Wilke, *Pedro Javier Lloreda Juardo, *Teakyung Um, *Robert Lundberg, and *Amelia Plunk

We are investigating freeze casting to create iron foams with various pore morphologies designed to improve the lifetime of materials used in high-temperature redox processes, like iron-air batteries and chemical looping combustion. We are using in operando X-ray microtomography to study the evolution of structure, porosity, and extent of reaction in freeze-cast, lamellar iron foams during redox cycling.

Microstructural Evolution in Freeze-Cast Materials

Kristen Scotti, Ming Chen, and Jesse Ji; co-advised by Prof. Peter Voorhees

As part of NASA's Materials Lab Open Science Campaign, directional solidification experiments will be conducted on the International Space Station, and freeze-casted samples will be sent back to Northwestern University for microstructural investigation. The aim of this work is to produce benchmark data necessary to advance the freeze-casting technology for both terrestrial and space-based materials processing, including producing data applicable for testing three existing freeze-casting models.

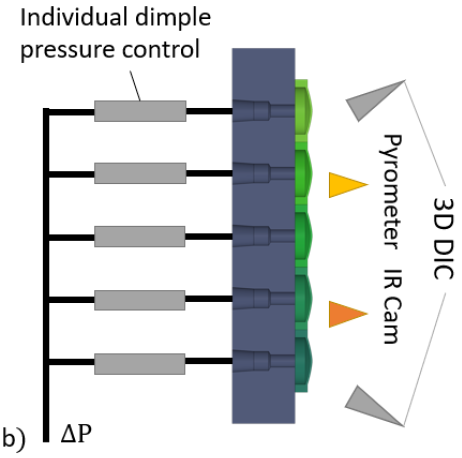

High-Throughput Creep/Oxidation Testing of Compositionally-Graded Co-Ni-Fe Superalloys

Tiffany Wu, KenHee Ryou, and Ryan Zhou, in collaboration with Prof. Jian Cao and Prof. Ian McCue

This project investigates mini-bulge testing of a graded Co-Ni-Fe alloy array, fabricated by directed energy deposition, to rapidly characterize key design-relevant properties of alloys at room and elevated temperatures. Image courtesy: Prof. Jian Cao

Al-Cu Creep Resistant Alloys

Dr. Jie Qi, Dr. Jovid Rakhmonov, and *Dr. Christoph Kenel in collaboration with Dr. Amit Shyam, ORNL

We study the role of intradendritic θ' and L12 (Al3Zr) precipitates, as well as grain-boundary θ particles, on the creep resistance at 300 șC of a series Al-Cu-Mn-Zr alloys, deformed either in tension or in compression.

Replacing Cerium with Mischmetal in Cast Aluminum Alloys

Jie Qi

Cast, near-eutectic aluminum-cerium (Al-8-12 wt% Ce) alloys show good creep resistance up to 300 șC, coupled with good coarsening resistance. Our research focuses on replacing the Ce with Ce-La-based Mischmetal (MM). The novel Al-MM alloys is lower in cost, energy consumption, and CO2 footprint during production than the Al-Ce alloys. Further elemental addition will provide additional strength to these Al-MM eutectic alloys.

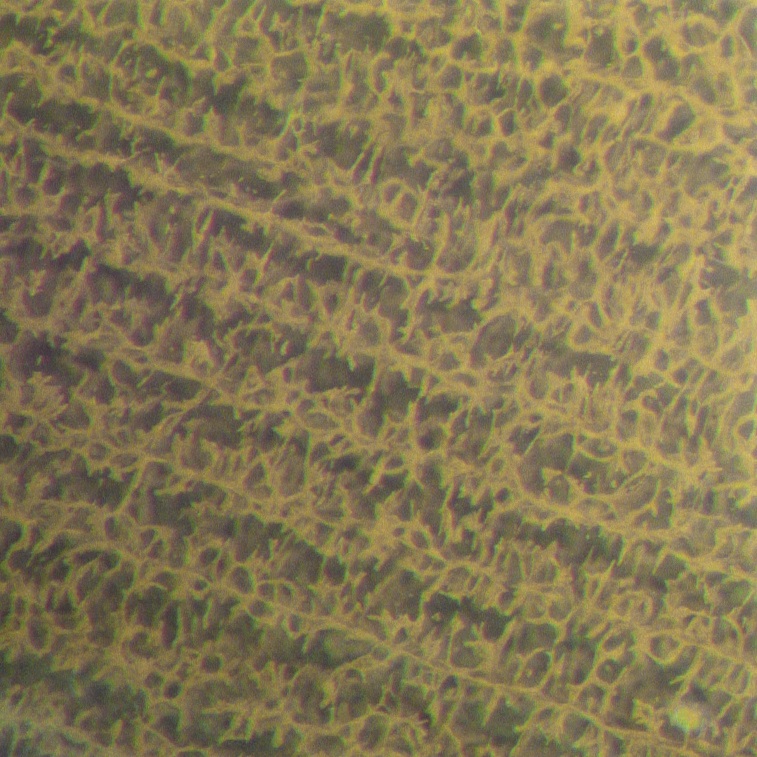

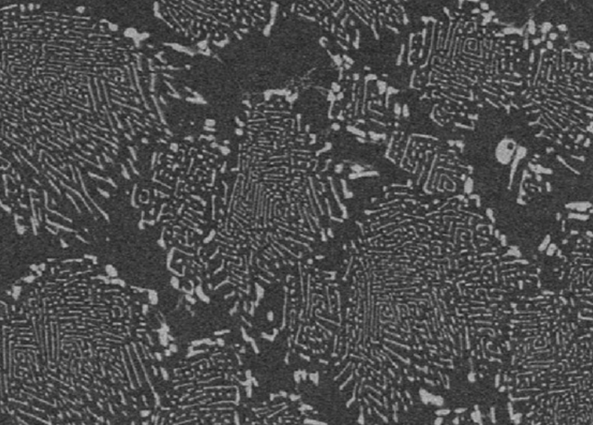

Cobalt-based superalloys

Hyeji Im, Davin Yoo, *Brandon Ohl, *Dr. Fei Xue, *Dr. Jacques Perrin Toinin, *Tony Chung, *Fernando Reyes, *Francesca Long, *Chunan Li, *Hyeji Park, *Dr. James Coakley, *Dr. Peter Bocchini, and *Dr. Daniel Sauza; in collaboration with Prof. David Seidman

We are developing new high temperature alloys based on Cobalt. Methods such as creep and hardness tests are used to investigate the mechanical properties of these alloys and Atom Probe Tomography is utilized to study the structure.