Pyrometallurgical recycling of "black mass" from spent lithium-ion batteries

Ming Chen, Na Gong, Maryam Al-buainain

The use of lithium-ion batteries (LIBs) in portable electronics, electric vehicles, and energy storage systems has grown very rapidly due to LIBs' high energy density, long lifespan, and fast charging. While most of these batteries are currently in service, a tsunami of spent batteries can be expected soon, as batteries reach the end of their lives. Spent batteries contain valuable elements - lithium, nickel, manganese, cobalt - for which recycling is desirable not only for economical reasons, but also to avoid land-filling and to decrease ore mining, thus improving battery sustainability. While it is economical to recover lithium, it is difficult to develop a robust, economical and sustainable process to recover the mix of Ni, Co, and Mn oxides, which constitute a significant portion (25-35 wt%) of black mass. Currently, to recycle these elements into new cathodes, the black mass must be separated, purified, and reduced into individual pure elements, which are then reoxidized. These steps release a considerable amount of CO2 and other deleterious waste streams (e.g., acid for leaching). In this project, we study the recycling of "black mass" from spent lithium-ion batteries via pyrometallurgy in a sustainable manner, focusing on thermochemistry and resulting microstructure of stable end products; in-situ x-ray diffraction provides a window on the kinetics of reactions, as well as the formation and disappearance of intermediate products.

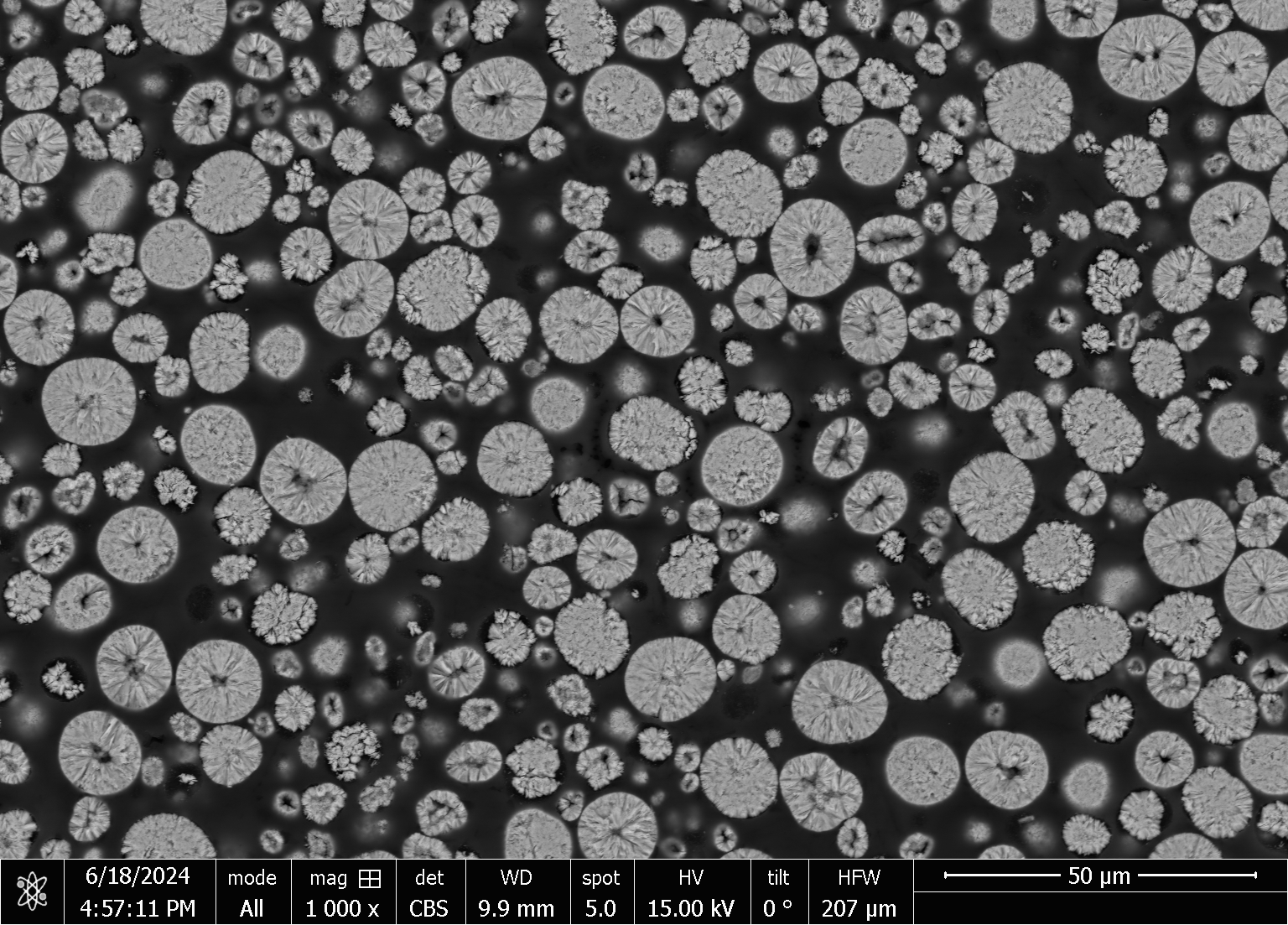

Back-scattered electron (BSE) micrograph of the cross-section of Ni0.8Mn0.1Co0.1(OH)2 powders for hydrogen reduction

Funding support

- Paula M. Trienens Institute For Sustainability and Energy